Automatic chamber type dry HGMS KJLGL-1500

Automatic chamber type dry HGMS KJLGL-1250

Automatic chamber type dry HGMS KJLGL-1250

Automatic chamber type dry HGMS KJLGL-1000

Automatic chamber type dry HGMS KJLGL-750

Automatic wet chamber type HGMS KJLSL-1250

Automatic wet chamber type HGMS KJLSL-1000

Automatic wet chamber type HGMS KJLSL-750

Automatic wet chamber type HGMS KJLSL-500

Fengkai 1000T / D feldspar turnkey project

KJLSL-500GG successful case of processing plant in Boluo, Huizhou

Successful cases of Indian customer's whole line project

Hunan Hengyang Jiepai ceramic raw material company

Successful trial production of turnkey project in Vietnam

KJLSL-1500 successful case in Hunan province

KJLSL-500QG successful case for feldspar processing in Xinyang, Henan

KJLSL-750 successful case in Shandong Yantai

KJLSL-500 successful case in Guangdong Qingyuan Yuantan ceramic raw material factory

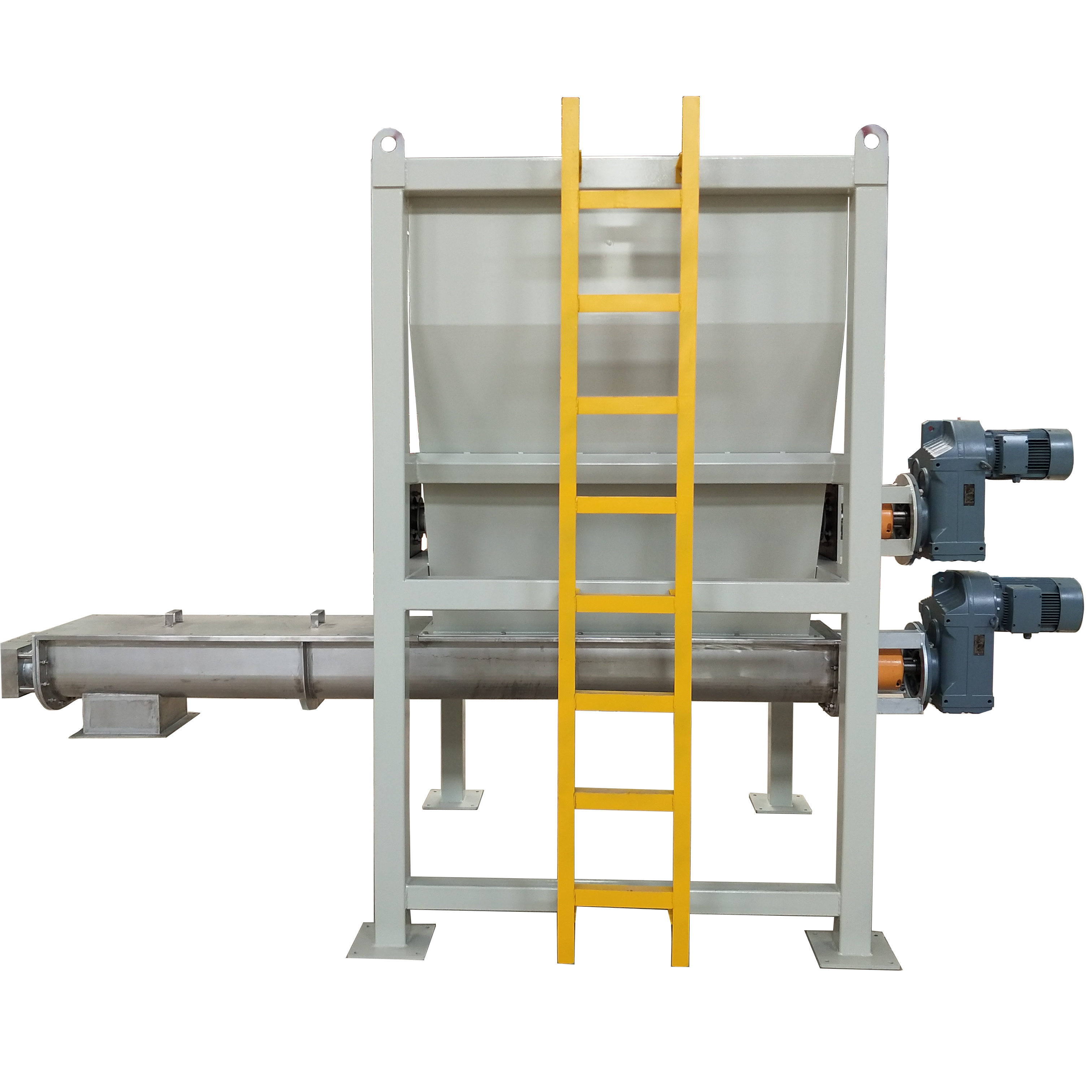

Shaftless screw conveyor of a sewage treatment plant in Shunde

13431631906

0757-88811782

13431631906

fskaijiali@163.com

764331226

61 Anhua Road, Fuwan Town, Hecheng street, Gaoming District, Foshan City

更多详情,欢迎扫一扫

在线客服

在线客服

扫一扫添加好友