The factory had two production lines, each of which used three 1500 vertical rings for three-stage iron removal. Each production line produced 400 tons of finished products every day. The iron content of raw materials produced was more than 0.14%, and the whiteness was between 48-52 degrees. Because the quality of raw materials produced is not up to standard, four KJLSL-500G high grade magnetic sepeartor of our company are added to each production line after the vertical ring. After adding equipment, each production line produces 400 tons of finished products every day, with iron content less than 0.1% and whiteness more than 60 degrees.

当前位置:

当前位置:

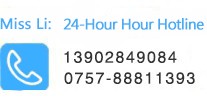

在线客服

在线客服